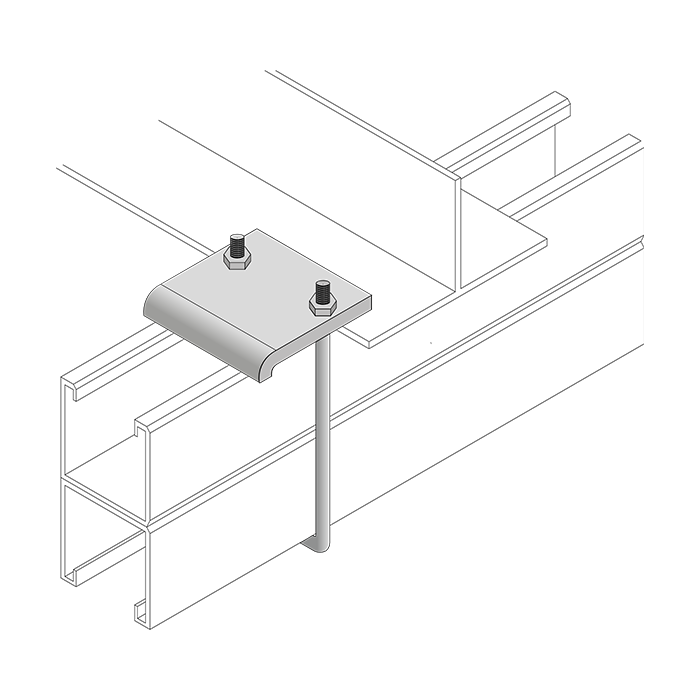

A wide range of articles which permit an easier fixing of cable trays and ladders in order to achieve the best solution for every requirement.

Among our bolts, shelves and plates, you will find:

Cable trays are used in the industrial plants to protect the laid cables. Specifically, the PS and AR perforated series are characterized by more lightness and by a good ventilation of the cable inside. The typology FC (closed bottom) is particularly suitable for environments where the cable isolation is essential.

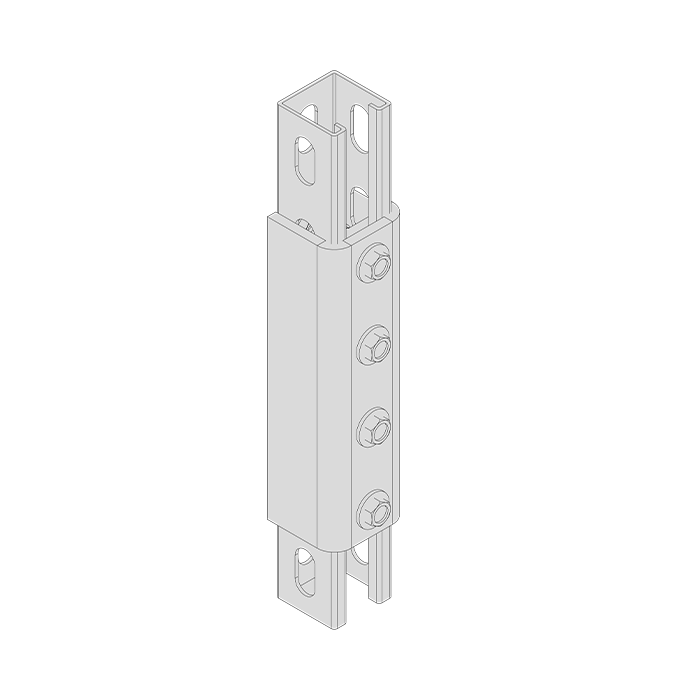

Thermal expansion: Our joints with crossed slots allow an even greater deviation between the elements, recovering any possible expansion without damages.

Electrical continuity: The electrical continuity of the cable trays is guaranteed by the correct assembly of joints and/or the copper bonding jumper; for this purpose, properly marked grounding holes are made on the cable trays and cable tray accessories.

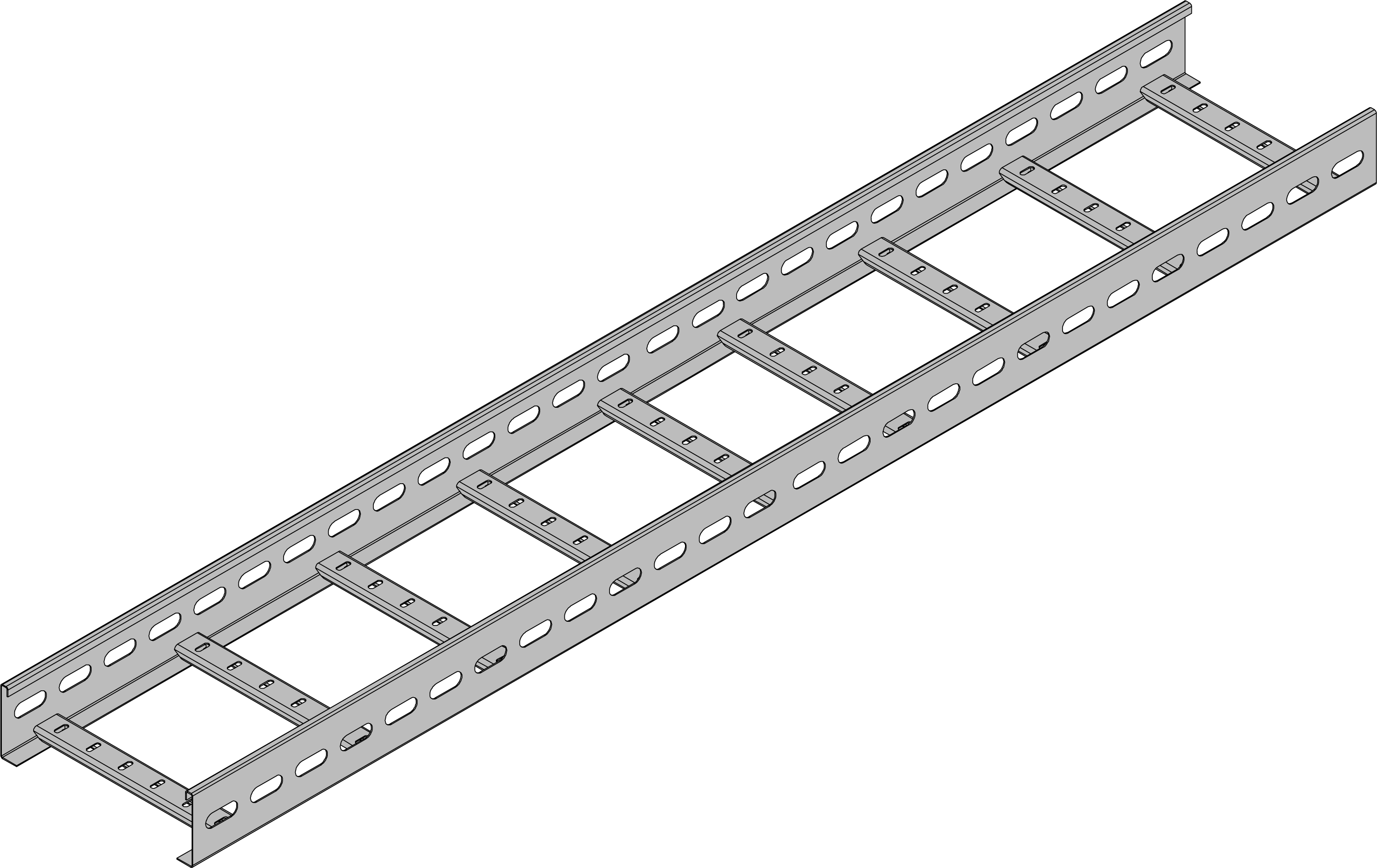

Cable ladders are designed to support high linear loads and to permit a higher ventilation in order to mantain a constant cable temperature inside, even with cable tray covers. For this reason, cable ladders are mainly suitable for energy cables installations.

Thermal Expansion of cable ladder parts: Our joints with crossed slots allow an even greater deviation between the elements, recovering any possible expansion without damages.

Electrical Continuity: The electrical continuity of ladder cable trays is guaranteed by the correct assembly of joints and/or the copper bonding jumper; for this purpose, properly marked grounding holes are made on the cable trays and related accessories.

Spina Group offers a wide range of electrical cable tray accessories, ladder cable tray accessories, metal cable tray accessories, cable tray fixing accessories, articles which permit an easier fixing of cable trays and ladders in order to achieve the best solution for every requirement.

Do you have a question or need specific information? Write to us and we can best advise you.

Our technicians will be able to support you in analyzing all your needs and identifying the most suitable product for your needs