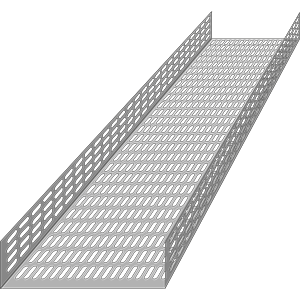

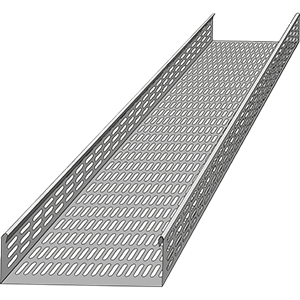

Spina Group designs and manufactures a complete range of cable trays brackets, supports, and hardware components to ensure fast, safe, and durable installation of cable management systems.

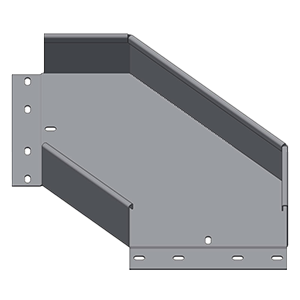

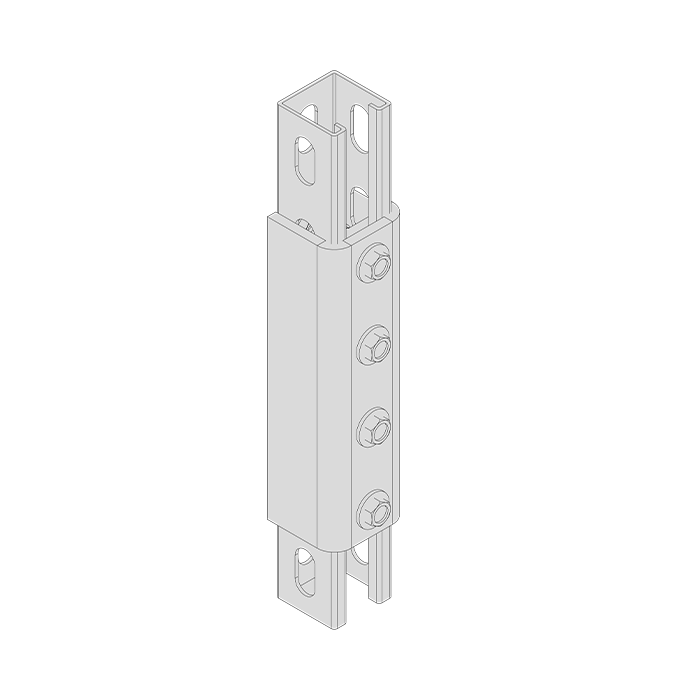

Our fixing hardware includes angle beams, steel brackets, and support plates engineered to guarantee excellent load capacity and resistance to vibration and corrosion. Each component is designed for compatibility with Spina Group cable trays and cable ladders, ensuring a consistent and modular installation.

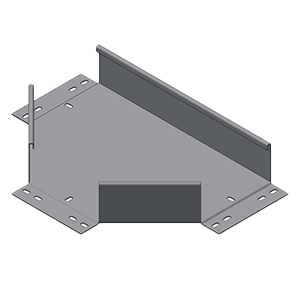

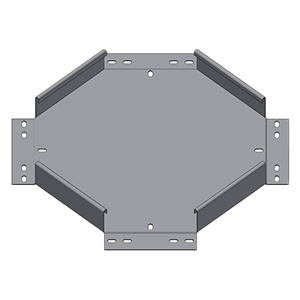

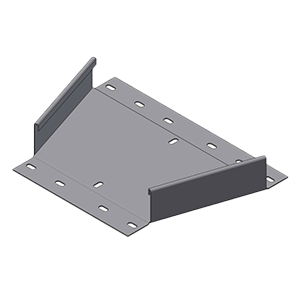

The product line covers a full set of cable ladder fittings, including connectors, clamps, cover clamps, and expansion accessories, all designed to facilitate assembly and maintenance operations.

Manufactured in Hot-Dip Galvanised (HDG), stainless steel, or aluminium, our angle beam steel supports and fixing plates are suitable for industrial environments such as energy, process plants, and infrastructure projects.

Additional accessories such as protector rolls, collars, shelves, and mounting hardware complete the range, providing engineers and installers with a reliable and fully compatible system for every requirement.