Essential tools and equipment designed to elevate precision and efficiency in mechanical maintenance and calibration tasks. Discover a full selection of portable and stationary testing and calibration instruments for electrical and pneumatic systems, as well as specialized machinery for lapping, beveling, milling, and bending. Our high-accuracy test and calibration benches for valves are crafted to support stringent quality control, ensuring optimal functionality and compliance across your operations.

Portable & stationary testing & calibration tools for electrical and pneumatic equipment

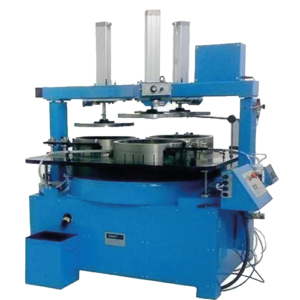

Machines for lapping, beveling, milling, bending

Test & calibration benches for valves

We offer a versatile selection of high-performance machinery and tools essential for workshop efficiency and precision. From bench and portable tools to robust fabrication and welding machines, our range is designed to support all levels of mechanical and structural work. These tools are built to withstand rigorous daily use, ensuring reliability and quality for fabrication, assembly, and maintenance tasks in demanding environments.

Featuring durable workbenches, cabinets, and shelving systems—including cantilever models—this category supports streamlined storage and access to tools and materials. For heavy-duty handling needs, we offer advanced lifting systems, cranes, and overhead cranes, designed to ensure secure and effective movement of heavy components. Each solution is engineered to optimize productivity and maintain safety in industrial settings.

Specialized equipment for maintaining and servicing heat exchanger components. This includes robust systems for bundle extraction, lifting, and precise cleaning to ensure optimal heat exchanger performance. We also offer advanced tube-to-tubesheet orbital welding solutions, along with efficient tube insertion and pulling systems, all engineered to support precise, safe, and efficient maintenance in demanding industrial applications.

Do you have a question or need specific information? Write to us and we can best advise you.

Our technicians will be able to support you in analyzing all your needs and identifying the most suitable product for your needs