Spina Group designs and supplies industrial grounding systems that guarantee the safety of goods and people, using high quality components to protect against atmospheric discharges for earthing systems.

Grounding means the set of actions and systems aimed at bringing a metallic element to the electric potential of the ground. It is important to ensure grounding where dangerous situations can occur when parts of the electrical system that are not normally live, due to failures or unforeseen events, acquire an electrical potential with respect to the ground.

Earthing, in particular, protects people from the risk of electrocution, in practice from “indirect contacts”. It consists of one or more interconnected dispersers placed in the ground and a series of earth and protection conductors which connect the aforementioned disperser to the user appliances.

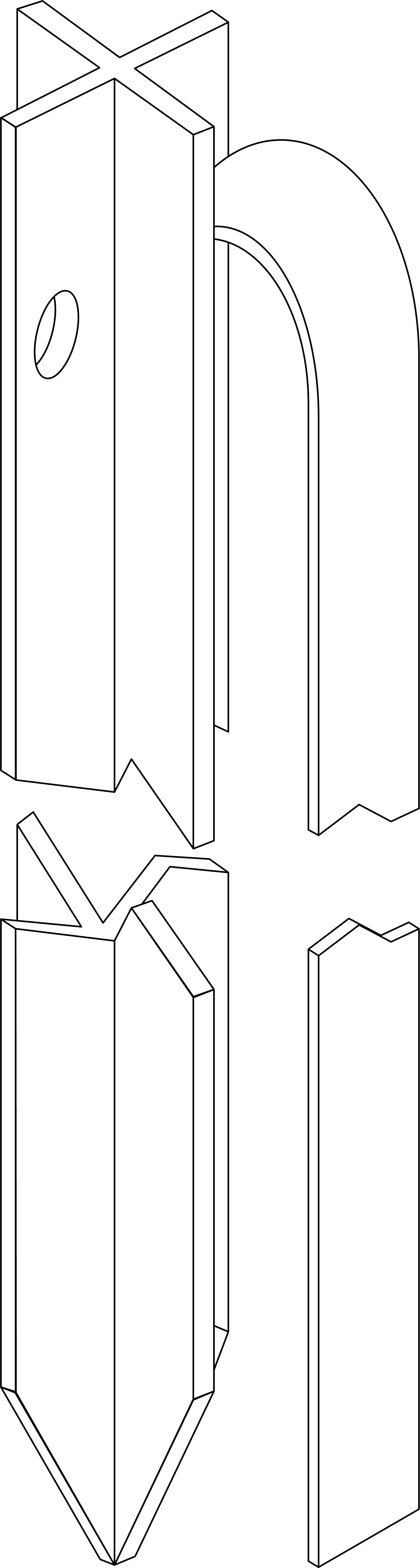

A wide range of earth rods, such as round section ground rods, T section ground rods, L section ground rods, X section ground rods, ground plates and accessories, designed according to the size of the currents that it disperse into the ground.

Spina Group offers a wide selection of accessories both for the protection against direct and indirect electric shock that ensure protection of the system from atmospheric discharges.

A wide selection of clamps, plates, turnband, bonding bars, terminal boards, bar insulators and bridge cables suitable for earthing stainless steel, copper and nickel-plated brass pipes.

Tools for electrical connections, electromechanical applications, transformer rooms compliant with national and foreign regulations. Sections and shaping different from the standard can be supplied on request. The products comply with the main national and international standards and with specific customer requests.

Spina offers a wide selection of inspection sumps in anti-corrosive plastic, available with removable bottom, carriageable cover, suitable for cable and earthing connection.

Overvoltage surge arresters (also called SPD – Surge Protection Device) are mechanisms that allow to protect electrical equipment from overvoltages by absorbing the generated current. They can also be inserted in an already existing system in order not to modify the operation of the system.

Need help?

Get in touch

Do you have a question or need specific information? Write to us and we can best advise you.

Request a quote

Our technicians will be able to support you in analyzing all your needs and identifying the most suitable product for your needs

Download the catalogue

Download our PDF catalog to get all the detail information related to this product category