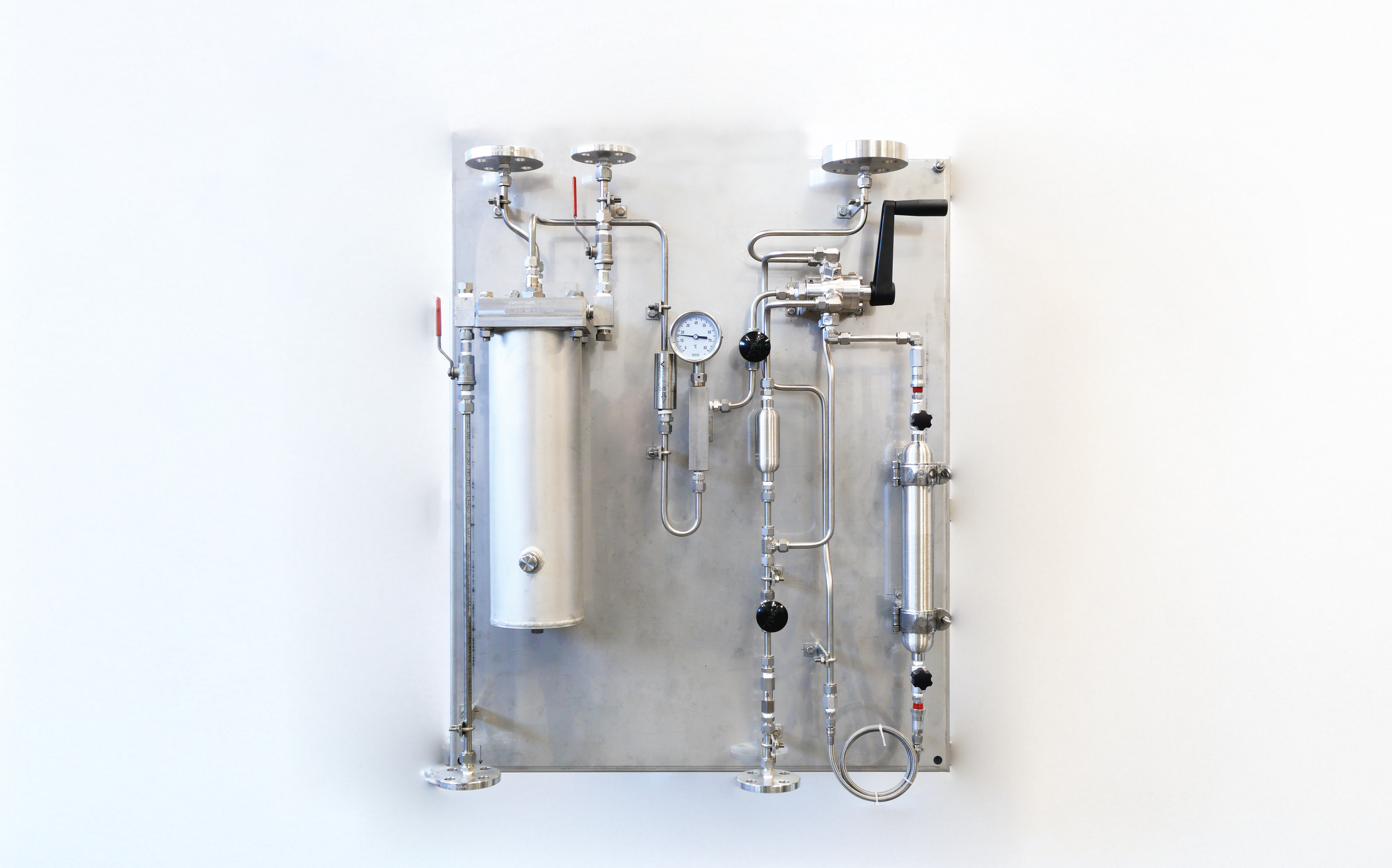

All our systems can be supplied on a selfsupporting rack or suitable for installation on existing poles and are mounted on Painted CS or SS plates where there are installed and tested all the components. Our standard material for components in contact with the fluid is the AISI 316/316L while special materials (e.g. Inconel 625 or Hastelloy C276) are used for those processes with critical pressure and temperature conditions or having contaminants that would physically or chemically affect the SS.

Stream heaters, Purge Systems and filters, Canopies, Cooled / heated / pressurized cabinets can be provided in order to allow the quickest and the safest sampling in any climatic condition.

Our tailored systems are designed and manufactured by us in order to comply with any kind of installation condition and type of process foreseen by customer’s specifications.

Samplers for liquids

Samplers for gases

Samplers for multi-phase fluids

Need help?

Get in touch

Do you have a question or need specific information? Write to us and we can best advise you.

Request a quote

Our technicians will be able to support you in analyzing all your needs and identifying the most suitable product for your needs

Download the catalogue

Download our PDF catalog to get all the detail information related to this product category